100 hour print

Large Format Printing

In selecting 3D printers one of the specifications that one considers is how large an object can you print. Seldom do you actually print really large models, but it is nice to know that you can. The problem with large prints is that they take a lot of time and the long the print the higher the chances of something going wrong.

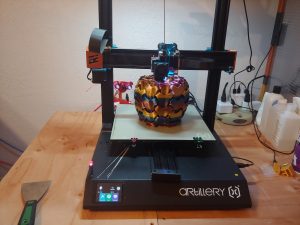

This print is a light shade. The model is by Sid Naique. The filament is CC3D’s Gradually Changing Color PLA Rainbow Multicolored Metallic. The Printer is an Artillery Sidewinder X1 (v4+) with a few upgrades. I will put all of the technical details below for those who are interested. IdeaMaker extimated print time as 88 hr 43 min. Octoprint Estimated 99 hr 23 min. The actual time was 97 hr 54 min.

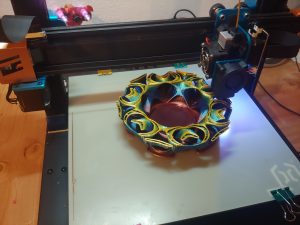

At 12 hours

At 28 hours

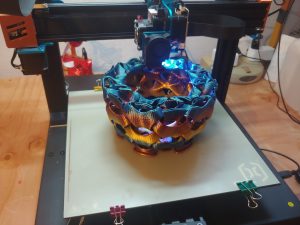

At 40 hours

At 55 hours

At 60 hours

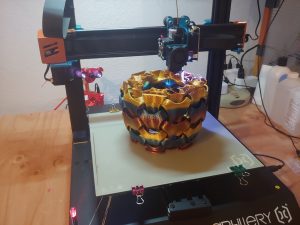

At 66 hours

At 75 hours

At 80 hours

at 94 hours

Finished

Finished

The technical bits

Printer Config

The Printer for this project is an Artillery Sidewinder X1 (v4+). The plus on that is because it has the latest release extruder head assembly which is not quite a month old.

Where the Sidewinder has a great heated bed, mine has a .05 mm dip in the center, so I have added a Garolite G-10/FR4 Sheet to the top of it, which really helps bed adhesion.

The nozzle for this print is the Micro Swiss Plated 0.4 mm which I have had exceptional performance out of.

The print was controlled by Octoprint.

Print Error

If you look carefully you will see that there is about a 2mm shift of the print to the right at about hour 58. We had a short power interruption of about 1 minute. Thankfully the printer resummed, but it had the slightest shift in the print.

Slicer Settings

The slicer used for this project is Idea Maker. The entire slicer profile is here. however, the primary settings are:

- Layer height: 0.16 mm

- Infill: 10%, Gyroid

- Extruder Temp: 212c

- Bed Temp: 58c

- Print Speed: 55 ms/s

- Flow rate: 96%

- Bed Adhesion: Raft

- Supports: None

With the Plated nozzle, I bumped the extruder temp up a couple degrees.I normally print PLA at around 60mm/s but bring it down when I want a good looking finish.

This model was so big, I did not want any adhesion problems so I elected to have a raft on this print.

In retrospect, I should have sliced this to print in Vase Mode, I probably would have save 10 hours on the print.